Titanium

$25-30B market- High strength-to-weight

- Corrosion resistant

- Biocompatible

Leading the domestic production of titanium, magnesium, aluminum, zirconium, and hafnium with modernized carbochlorination technology. Securing America's supply chain independence.

America's dependence on foreign critical metals threatens our national security, economic stability, and technological leadership.

Reduce dependence on foreign suppliers for defense-critical materials

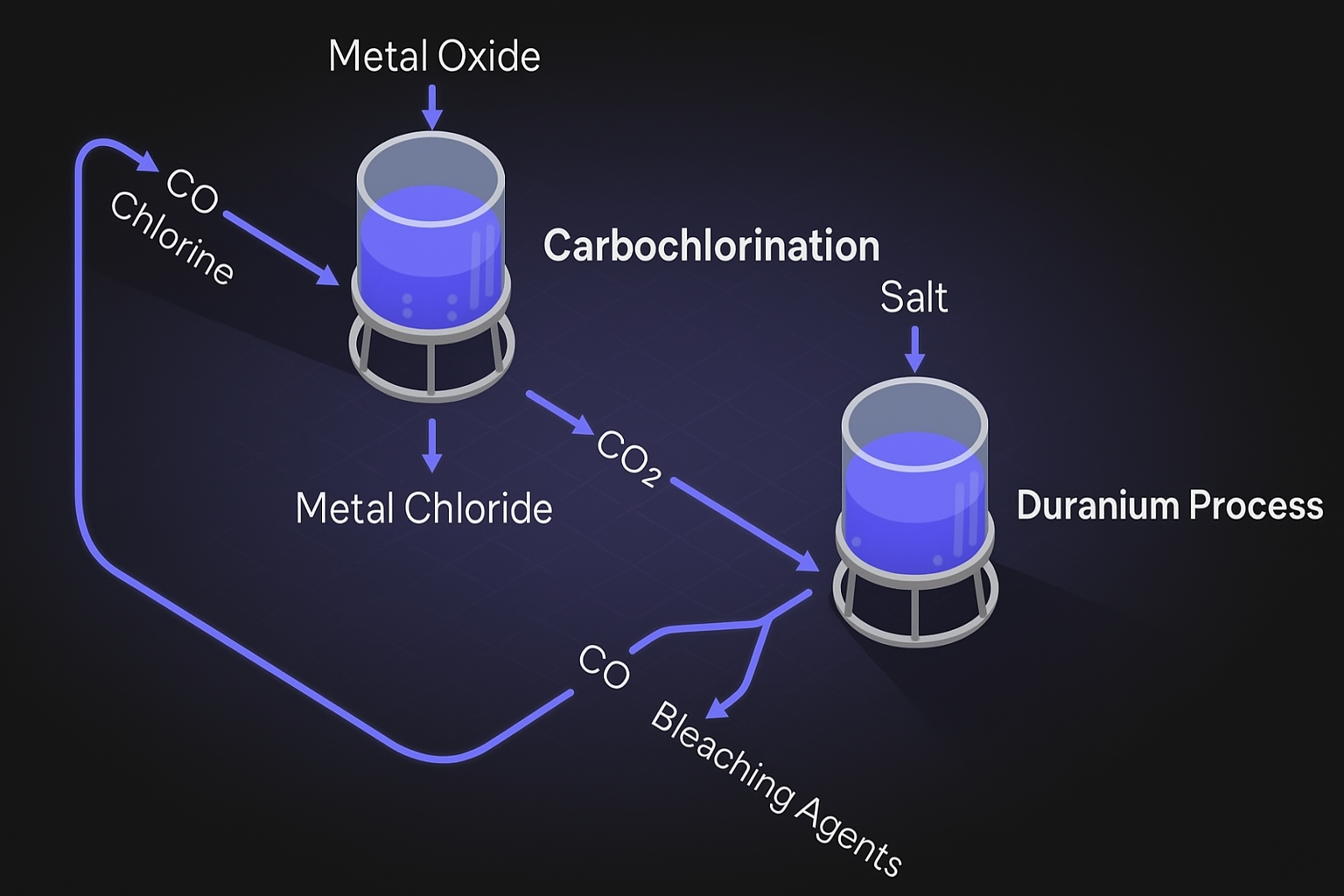

Modernized carbochlorination process with superior efficiency

Domestic production ensures reliable, consistent material supply

High-skilled manufacturing jobs in American communities

Five essential lightweight metals that power America's aerospace, defense, and advanced manufacturing industries.

Our modernized carbochlorination process delivers superior efficiency, lower costs, and reduced environmental impact compared to traditional methods.

Advanced ore preparation and purification using optimized carbochlorination chemistry

Controlled carbochlorination at optimal temperatures for maximum yield and purity

Efficient separation and purification to produce high-grade metal products

Optimized process parameters reduce energy consumption compared to traditional methods

Advanced purification techniques ensure highest quality metal output

Closed-loop systems minimize waste and environmental impact

The U.S. imports over 90% of its critical metals, creating a $50+ billion annual trade deficit and supply chain vulnerability. Duranium's domestic production addresses this strategic challenge.

30-50% lower costs than imported alternatives

Eliminate geopolitical supply chain risks

1,000+ high-skilled manufacturing jobs

Duranium is led by founders with deep experience across advanced manufacturing, electrochemistry, and national security supply chains.

Ready to discuss partnership opportunities, investment, or learn more about our technology? We'd love to hear from you.

info@duranium.com

partnerships@duranium.com

1234 Star Trek

Alameda, California

United States

Strategic investors, OEM customers, government contracts, technology licensing

We'll get back to you within 24 hours

Join us in reshoring critical metals production and building a more resilient supply chain.